-

بلبرینگ جامد JDB یاتاقان فلنج گرد برنزی خود روان کننده بدون روغن متریک JFB650

بلبرینگ جامد JDB یاتاقان فلنج گرد برنزی خود روان کننده بدون روغن متریک JFB650 -

بلبرینگ جامد JDB یاتاقان روانکاری جامد استاندارد از نوع شانه ای فلنج دار GB71 NAAMS

بلبرینگ جامد JDB یاتاقان روانکاری جامد استاندارد از نوع شانه ای فلنج دار GB71 NAAMS -

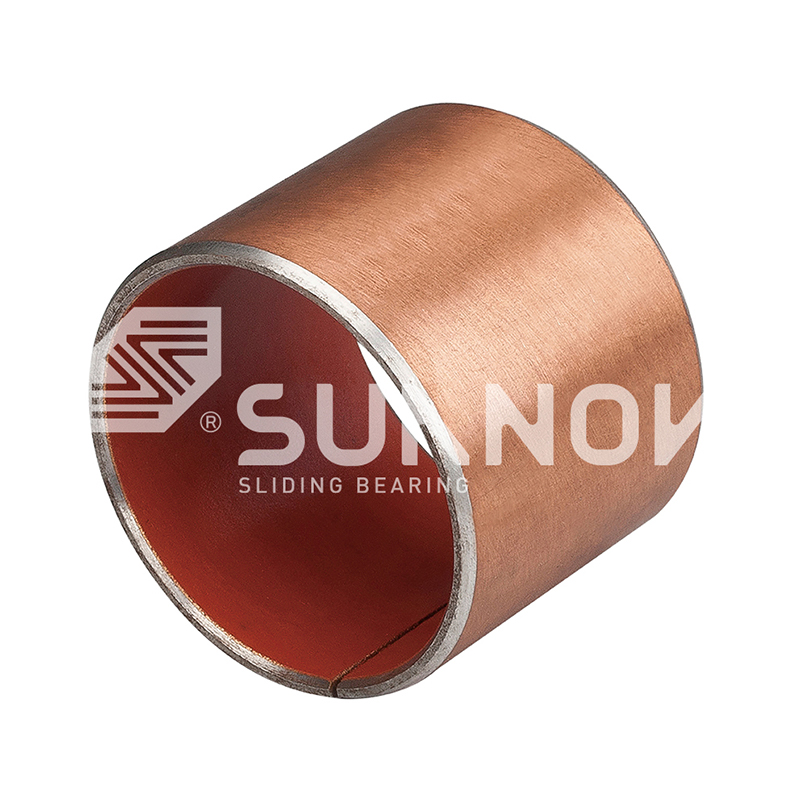

بلبرینگ دو فلزی نگهدارنده روغن 200 یاتاقان فلنج برای خود جاذبه خود مقاوم در برابر سایش

بلبرینگ دو فلزی نگهدارنده روغن 200 یاتاقان فلنج برای خود جاذبه خود مقاوم در برابر سایش -

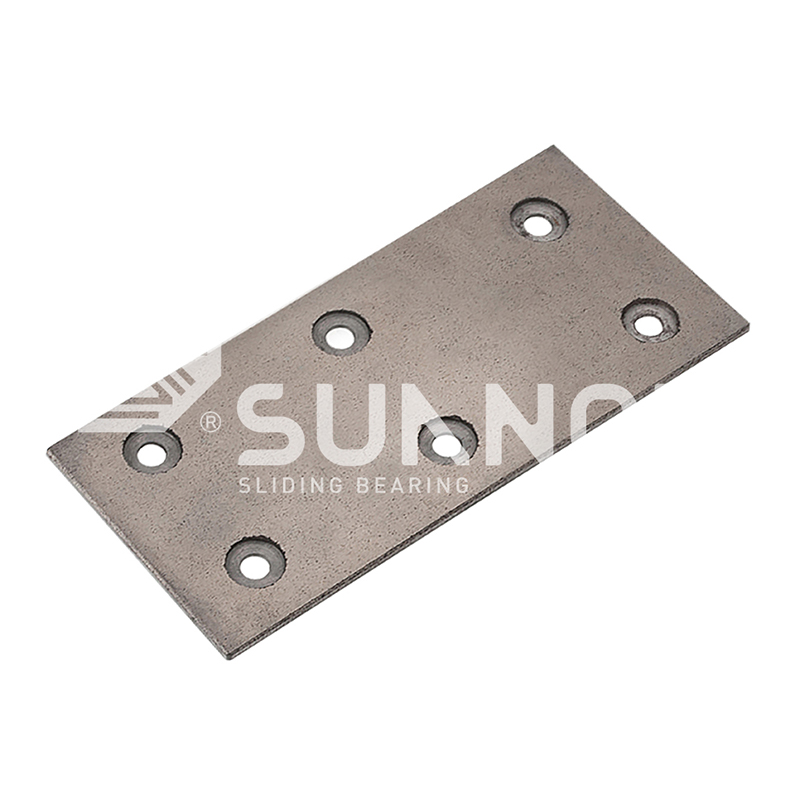

بلبرینگ دو فلزی نگهدارنده روغن 200#P5 صفحه سایش به روغن نگهدارنده خودکشی-سطح یاتاقان اصطکاک کم

بلبرینگ دو فلزی نگهدارنده روغن 200#P5 صفحه سایش به روغن نگهدارنده خودکشی-سطح یاتاقان اصطکاک کم -

-

-

-

یاتاقان دو فلزی JF-800 بلبرینگ فلنج متریک JF-800F استاندارد

یاتاقان دو فلزی JF-800 بلبرینگ فلنج متریک JF-800F استاندارد

پیش بینی طول عمر و مقاومت در برابر سایش بوش برنزی بدون روغن در شرایط عملیاتی شدید

اخبار صنایع-I. انتقاد از خود روانکاری در یاتاقان های صنعتی

In heavy machinery, construction equipment, and specialized industrial plants, reliable motion control often depends on bearings operating outside the parameters of traditional oil or grease lubrication. را oilless bronze bushing is the engineered solution for these challenging environments, relying on embedded solid lubricants (typically graphite or PTFE plugs) to ensure low friction and sustained performance under high loads, slow speeds, or extreme temperatures. Understanding the interplay between load, speed, and temperature is paramount for B2B procurement specialists and design engineers tasked with maximizing equipment uptime and minimizing maintenance cycles. Zhejiang Shuangnuo Bearing Technology Co., Ltd. متخصص در تولید طیف متنوعی از محصولات آلیاژ مس خود روان شونده است. Our dedication to quality begins at the source: we insist on independent casting production of raw materials using advanced processes like centrifugal casting, continuous casting, and metal mold casting to ensure the quality of the brass, aluminum bronze, and tin bronze alloys. The entire production process, from material composition verification (three-time spectrometer testing) to integrated processing on over 80 sets of advanced CNC equipment, ensures product integrity and minimizes lead times. We adhere to a business philosophy of "moderation and harmony, integrity-based," committing to professional product application solutions and personalized, tailor-made design.

Round Self-lubricating JOST Oilless Brass Flanged Guide Bearing Bushing

II. فاکتور PV: محدودیت های بار و سرعت

The most fundamental indicator for predicting the performance of an oilless bronze bushing is the Pressure-Velocity (PV) factor, which is the product of the contact pressure (P) on the projected bearing area and the surface sliding velocity (V). This parameter directly correlates with the heat generated at the bearing surface (friction power) and thus dictates the bearing's thermal stability and wear rate. Operating beyond the Limiting PV will rapidly break down the solid lubricant layer, leading to metal-on-metal contact and catastrophic failure.

الف ارزیابی حد PV بوش برنزی بدون روغن

ارزیابی حد PV بوش برنزی بدون روغن برای تعیین مناسب بودن یاتاقان برای کاربرد ضروری است. PV محدود کننده یک مقدار واحد نیست. به طور قابل توجهی بین عملکرد مداوم و متناوب متفاوت است، زیرا عملکرد مداوم زمان کمتری را برای اتلاف گرما می دهد. Products like solid inlaid self-lubricating bearings, which benefit from the high thermal conductivity of the bronze base, often have a much higher Limiting PV than sintered bimetallic products in high-speed applications. Below is a comparative example of the limiting continuous PV factor for typical self-lubricating products:

| نوع بلبرینگ | روش روانکاری اولیه | PV محدود کننده معمولی (N/mm² * m/s) | تمرکز برنامه اولیه |

|---|---|---|---|

| برنز منبت کاری شده جامد | شاخه های گرافیت | ~ 1.0 - 1.6 | بار زیاد، سرعت کم |

| محصولات دو فلزی زینتر شده | لایه / روغن متخلخل متخلخل | ~ 3.0 - 4.5 | بار متوسط، متوسط / سرعت بالا |

III. محدودیت های حرارتی و تخریب مواد

دما قاتل خاموش طول عمر بلبرینگ است. Frictional heat generated from the PV factor, combined with high ambient operating temperatures, dictates the efficacy of the solid lubricant and the stability of the bronze substrate. Every copper alloy has a critical temperature threshold. فراتر از این حد باعث نرم شدن ماتریس برنز شده و سایش را به میزان قابل توجهی تسریع می کند.

الف تاثیر دمای بوش برنز بدون روغن بر طول عمر

تأثیر دمای بوش برنز بدون روغن بر طول عمر اغلب به نقطه اکسیداسیون و نرم شدن آلیاژ برنز مرتبط است. Tin bronze (e.g., CuSn12) offers better temperature stability and greater hardness than standard brass in elevated temperature environments. Furthermore, if the temperature is high enough, the solid lubricant (such as graphite) can oxidize or degrade, preventing the formation of the crucial transfer film on the mating surface, which is essential for self-lubrication. Therefore, the selection of the bronze base material is as critical as the lubricant selection for applications over 150 degrees Celsius.

IV. تجزیه و تحلیل پیش بینی سایش و عمر خدمات

Predicting the service life of an oilless bronze bushing involves analyzing its wear rate, which is the slope of the wear depth over time. The lifespan ($L$) is often predicted using the formula $L = \frac{T}{K \cdot P \cdot V}$, where $T$ is the allowable wear depth and $K$ is the specific wear rate constant. The initial "running-in" phase is critical; a proper running-in establishes the solid lubricant film, drastically lowering the steady-state wear rate.

الف High Load Oilless Bronze Bushing Wear Rates

تحت بارهای استاتیکی یا دینامیکی بالا، نرخ سایش بوش برنز بدون روغن بار بالا به طور تصاعدی افزایش می یابد. تنش فشاری وارد شده بر یاتاقان تعیین می کند که روان کننده جامد چقدر می تواند به طور موثر به سطح شفت جفت منتقل شود. اگر بار خیلی زیاد باشد، شمع های روان کننده را می توان قبل از اینکه بتوانند عملکرد خود را انجام دهند خرد یا اکسترود کرد. Products made from robust aluminum bronze (e.g., CuAl10Ni5Fe4), manufactured with the quality assurance of Zhejiang Shuangnuo's proprietary casting, offer superior compressive strength and are preferred for severe high-load applications. نرخ سایش خاص ($K$) به طور قابل توجهی بر اساس فلز پایه تحت بارهای بالا متفاوت است:

| نوع آلیاژ برنز | قدرت جزء اصلی | نرخ سایش نسبت به برنج استاندارد | بار عملیاتی توصیه شده (P) |

|---|---|---|---|

| Brass (CuZn Series) | خوب | بالا (عمر سایش کمتر) | کم تا متوسط |

| قلع برنز (سری CuSn) | خیلی خوبه | متوسط | متوسط to High |

| آلومینیوم برنز (سری CuAlNiFe) | عالی | کم (طولانی ترین عمر پوشیدن) | بالا تا خیلی زیاد |

B. Centrifugal Cast Bronze Self Lubricating Bearing Performance

کیفیت پایه برنز اساسی است. Centrifugal cast bronze self lubricating bearing performance surpasses that of simple static castings due to the process creating a finer grain structure, reduced porosity, and higher material density. This enhanced microstructure improves the mechanical properties, providing a stronger, more wear-resistant base for the embedded lubricant plugs, thereby significantly contributing to a more accurate service life prediction for graphite plugged bronze. Our commitment to material composition monitoring and mechanical properties testing by national agencies ensures every batch meets the highest standards for durability and performance.

V. Quality Assurance and Customization for B2B Procurement

For B2B procurement, the ability to source complex, high-quality self-lubricating bearings with short lead times is vital. Zhejiang Shuangnuo Bearing Technology Co., Ltd. provides integrated production, from raw material casting to final CNC machining, ensuring control over the entire supply chain. Our focus is on providing professional product application solutions, including personalized, tailor-made design and customization based on customer product characteristics and application specifics. We provide customers with authoritative test reports to confirm material composition and mechanical properties, validating the technical specifications of our oilless bronze bushing products.

VI. دقت در محلول های خود روان کننده

Maximizing the service life and wear resistance of an oilless bronze bushing is an exercise in engineering precision, dictated primarily by managing the Limiting PV and temperature. By selecting the correct bronze alloy and self-lubricating design—supported by the material quality and manufacturing expertise of a specialized producer like Zhejiang Shuangnuo—designers can accurately utilize oilless bronze bushing PV limit assessment data to ensure reliable, long-term performance, transforming high-maintenance applications into self-sufficient systems.

VII. سوالات متداول (سؤالات متداول)

Q1: فاکتور PV چگونه با طول عمر مورد انتظار یک بوش برنزی بدون روغن ارتباط دارد؟

- A: ضریب PV (فشار x سرعت) مستقیماً با تولید گرمای اصطکاکی متناسب است. Operating above the Limiting PV accelerates the degradation of the solid lubricant film and the bronze matrix, leading to rapid, unpredictable wear and drastically reducing the expected lifespan.

Q2: What is the main benefit of using a centrifugal cast bronze self lubricating bearing performance over a static cast one?

- A: Centrifugal casting creates a denser, finer-grained microstructure in the bronze, which translates to superior mechanical strength, reduced porosity, and enhanced wear resistance. This foundational quality is critical for the long-term reliability of the self-lubricating bearing in high-stress applications.

Q3: Which bronze alloy is recommended for minimizing high load oilless bronze bushing wear rates?

- A: آلومینیوم برنز (به عنوان مثال، سری CuAlNiFe) به طور کلی برای به حداقل رساندن نرخ سایش در شرایط بار بالا توصیه می شود. It offers superior compressive strength and hardness compared to tin bronze or brass, allowing the bearing to withstand greater pressure without deformation or accelerated wear.

Q4: How does the oilless bronze bushing temperature impact on lifespan differ from a traditional lubricated bearing?

- A: While a traditional bearing risks lubricant breakdown at high temperatures, an oilless bronze bushing risks the oxidation or thermal decomposition of the *solid* lubricant (e.g., graphite) and the softening of the bronze matrix itself. Exceeding the material's critical temperature leads to failure due to material loss rather than fluid loss.

Q5: چرا پیشبینی عمر مفید برنز متصل به گرافیت ذاتاً دشوار است؟

- A: Service life prediction is difficult because the wear rate is highly dependent on environmental variables (dust, moisture) and the efficiency of the solid lubricant transfer film, which can vary with initial running-in quality and temperature fluctuations. برای دستیابی به پیشبینی دقیق، به ارزیابی حد PV بوش برنزی بدون روغن دقیق و کنترل دما نیاز دارد.